|

||||||||||||||||||||||||||||||||||||

|

Request a Quote

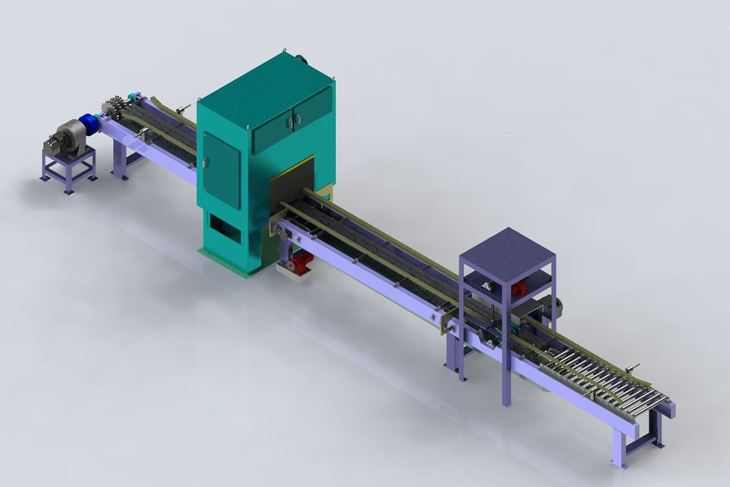

Battery Cutting MachineIt is a rotating wheel type Semi-Automatic Battery Cutting Machine of standard capacity 2-3 MT/hr. Battery will be punctured from bottom through cutter to drain the acid water from battery. Metal Cutting Steel Blades rotating at high speed fitted on base frame structure. Forward movement of batteries against blade/cutting wheels is facilitated with SS 316 mounted on long base frame. To cut different height batteries motorized gear screw arrangement can simultaneously move these two cutting wheels up & down.

After cutting the battery, plastic box is emptied manually by separating the Lead bearing material, grids & separators etc. Terminals are separated from the top lid. Subsequent crushing of Plastic Boxes is done in Plastic crusher and all lead bearing material is fed into charge for further smelting. Breaking System & Separation of Components

Battery Cutting and Punching Machine Benefits:

|

||||||||||||||||||||||||||||||||||||

|

Company

|